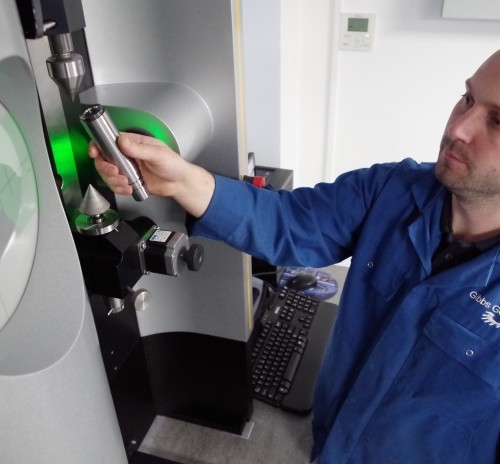

Gibbs Gears are passionate about producing quality gears, offering the most rigid quality control methods and procedures. We are approved to AS9100 Rev C and BS EN ISO 9001:2008 and provide gears to many blue chip companies.

Gibbs Gears has its own inspection department, which is furnished with the latest in CMM machines and metrology equipment. We use a Wenzel WGT280 (new 2013) and LH54 Gear Tec CMM, complete with gear measuring software to ensure that all measurements are meticulously and automatically checked.

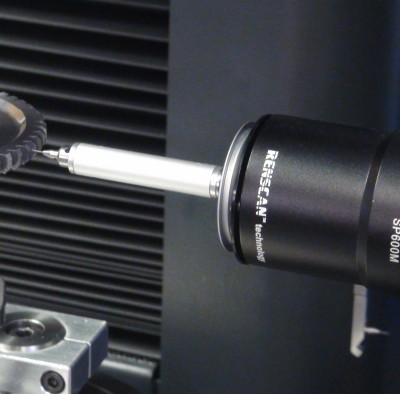

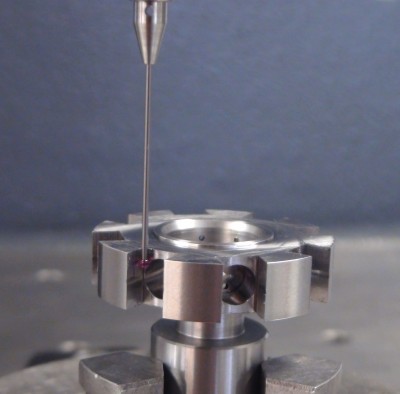

The CNC gear measuring machines comprises of a mechanical structure built from dark granite with 3 axis moving on precise air bearings, with a 4th axis precision rotary table. Machine movements and probing are controlled by Wenzel’s controllers with measuring points scanned by Renishaw continuous contact probing.

Software

A well-proven suite of programs allows all kinds of gears (spur, helical, bevel, worms, etc.) and other complex geometries such as shafts and cams, to be measured, simply and efficiently, with clear graphical reports produced.

Specification

The CNC Gear Checker can measure gears up to 500mm diameter, with modules from 0.5 up to 15, to VDI 2612/3 Group 1 accuracy specification. We also have a Zeiss DuraMax CMM with gear checking functions.

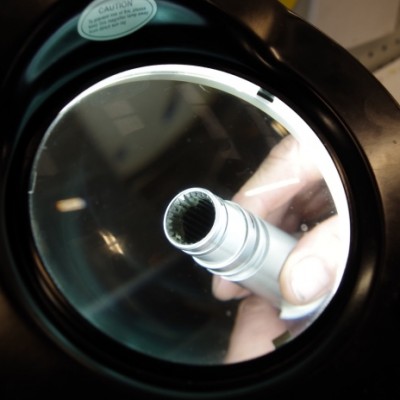

Zeiss DuraMax

Software

CALYPSO – PROVEN MEASUREMENT FROM CARL ZEISS, 3-D CAD BASED SOFTWARE.

We are fully committed to continuous improvement and work closely with our customers to ensure their complete satisfaction. Temperature controlled Inspection Department. Co-ordinate Measuring Machines, CNC Gear Checking Machine, Rolling gear tester and various other equipment Calibration traceable to national standards.

To discuss your quality gears requirements, contact us on +44 (0) 1296 739020.